"The Odd Likeliness of Ordinary Miracles"

Helen Green Ceramix Pit-fires and Raku

“The Odd Likeliness Of Ordinary Miracles”

Ritual Firings - Pit-firing & Raku, two distinct types of firing :

For Helen, a firing is always a kind of ritual, especially with raku and pit-firings which are always participative events. Many delicately crafted objects are handed over to the uncertainties of a unique kiln atmosphere and the result is an exciting transformation.

Our Annual pit-firing Ritual Grande Cuisson en Fosse

Fired for 12 hours in a pit, these objects take on their colours when they are incandescent, as the pores open. The colours are fixed when the pots cool off and are thus “painted with fire”! See some of my pit-fired pieces here.

“They Burn Mud, Don’t They?”

Our pit-firings are unique ceramic experiences, both participative and meditative, where considerable care and attention is brought to each step in the process. Just the colours are left to the whims of the 12 hour long fire. Each piece is white when it goes in but when it comes out it has been marked by elements animated in the flames, (wood, banana skins, copper and algae). The cooling process traps this tableau in the very pores of the pieces.

Pit-firing is considered an ‘alternative’ method of firing ceramics as the firing atmosphere is not as controllable as in most modern kilns. It is the opportunity to experiment and celebrate the ‘magic’ of chemistry in nature. The preparation time provides a moment to create clay ‘kiln gods’ out of fresh clay, and enjoy the musings of a night under the stars around an open fire.

To respect the regeneration of nature, we hold our pit-firing event just once per year, “Grande Cuisson en Fosse Annuelle” near Montpellier in the South of France. Many thanks to Rajaneesh Dwivedi for these photos of the event and to Remi Vionnet for a vidéo posted on our Facebook page!

Raku rituels

fast firings in less than 2 hours, with effects given thanks to thermal choc…

“Raku” refers to an alternative method of firing ceramics. It is a traditional tea-cup making technique in Japan (involving throwing, glazing and plunging the incandescent pot into water), as well as this method adopted and transformed by Paul Soldner (see quote below). Raku kilns are fuelled with gas or wood and are often quite make-shift, as they are made to suffer repeated thermal shocks and the side-effects thereof.

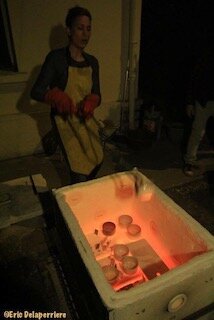

A Raku firing is also somewhat akin to a ritual. After glazing, the actual firing process takes about an hour, before the objects are taken out of a hot kiln (about 950°C) when they are still incandescent, which is very exciting to behold. With the thermal shock many things can happen to the pieces at this moment, they can be blackened in saw-dust, their glaze can crackle and ‘sing’ or undergo a reduction reaction rendering metallic finishes...

The pieces then cool off, the effects are trapped and the result is handed over to the odd and spirited likeliness of ordinary miracles.

It is therefore the genesis of the raku object which defines it and I like raku pieces to be made with such spontaneity that gestures and impulses are palpable.

Helen Green Ceramix, in collaboration with Alain Mombrinie, Archi Vase, Raku-Fired, 2016

"In the spirit of raku, there is the necessity to embrace the element of surprise. There can be no fear of losing what was once planned and there must be an urge to grow along with the discovery of the unknown. In the spirit of raku: make no demands, expect nothing, follow no absolute plan, be secure in change, learn to accept another solution and, finally, prefer to gamble on your own intuition. Raku offers us deep understanding of those qualities in pottery which are of a more spiritual nature, of pots by man willing to create objects that have meaning as well as function." - Paul Soldner, 1973

Many thanks to Eric Delaperriere for these images of the first firing of our unique HGAM RAKU kiln!